English

English-

Español

Español

-

Português

Português

-

Portugiesisch

Portugiesisch

-

Français

Français

-

日本語

日本語

-

Български

Български

-

한국어

한국어

-

Türkçe

Türkçe

-

Nederlands

Nederlands

-

English

English

-

Eesti

Eesti

-

Suomi

Suomi

-

বাঙ্গালি

বাঙ্গালি

-

беларуская

беларуская

-

Ελληνικά

Ελληνικά

-

Kreyòl ayisyen

Kreyòl ayisyen

-

עִברִית

עִברִית

-

हिन्दी

हिन्दी

-

Magyar

Magyar

-

íslenskur

íslenskur

-

Gaeilge

Gaeilge

-

italiano

italiano

-

Hrvatski

Hrvatski

-

Latinus

Latinus

-

latviski

latviski

-

Melayu

Melayu

-

Malti

Malti

-

Монгол

Монгол

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

Polski

Polski

-

عربي

عربي

-

Română

Română

-

русский

русский

-

slovenský

slovenský

-

Slovenščina

Slovenščina

-

Afrikaans

Afrikaans

-

svenska

svenska

-

dansk

dansk

-

український

український

-

o'zbek

o'zbek

-

Cymraeg

Cymraeg

-

Zulu

-

Tiếng Việt

Tiếng Việt

-

bosanski

bosanski

-

Deutsch

Deutsch

-

eesti keel

eesti keel

-

ไทย

ไทย

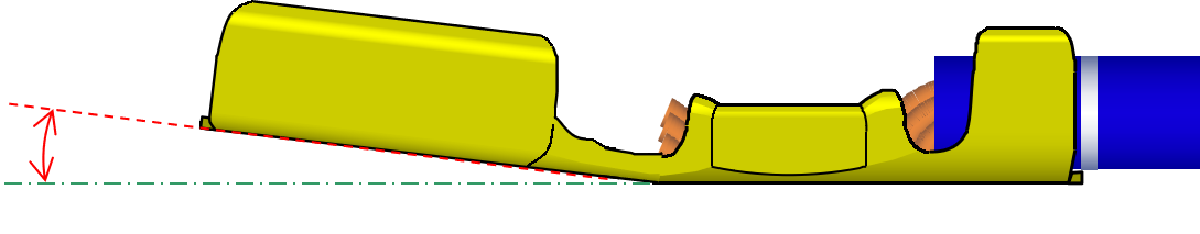

Bad terminal crimping factors (4)

Wed Sep 01 17:08:41 CST 2021

1.Mold damage

Due to abnormal operations (secondary crimping, etc.) and mold overload, the upper and lower crimping molds are scarred or cracked. Therefore, the inability to extrude the regular shape will cause big problems like burrs. Die abnormalities can be found by observing the crimping part.

Terminal deformation

The allowable range varies depending on the terminal, and is generally within ±5°. The twisted terminal will produce the same defect as the side bend.

2.Terminal deformation

Bend up:

The allowable range varies according to different terminals, generally within 3°. Terminals that are bent upward cannot be inserted into the shell. Even if they can be inserted, they will come off the nail and cause poor fitting on the other side 1.

Bend down:

The allowable angle varies somewhat depending on the terminal, and is generally within 3°. Terminals that are bent downward cannot be inserted into the shell, and even if the shell can be inserted, the nail will come off, and it will cause poor fitting at the other end.